Comprehensive Guide to Lift Repair Companies Near Me for Effective Lift Maintenance

Comprehensive Guide to Lift Repair Companies Near Me for Effective Lift Maintenance

Blog Article

Vital Factors to Think About for Elevator Maintenance

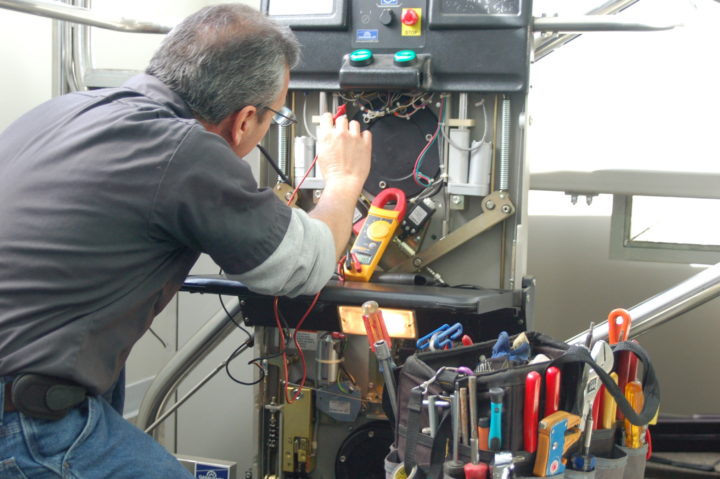

When it comes to the safe and effective operation of lifts, thinking about important maintenance variables is critical. It is imperative for constructing supervisors and upkeep workers to stay ahead of these elements to promote the elevator's efficiency requirements and compliance demands.

Routine Inspection Schedules

Conducting normal evaluations not only improves the general performance of the lift but additionally plays a crucial duty in abiding by safety and security laws and industry requirements. It guarantees that the elevator runs efficiently, decreasing the risk of unanticipated breakdowns that might trouble owners or concession safety and security. Additionally, routine assessments add to extending the life-span of the lift equipment, inevitably lowering upkeep costs and downtime.

To improve the examination procedure, numerous structure owners companion with certified lift upkeep firms that specialize in performing thorough assessments and offering punctual upkeep services. By prioritizing regular evaluation timetables, stakeholders can maintain the safety and security, integrity, and effectiveness of their elevator systems.

Proper Lubrication Methods

Effective lubrication practices are vital for keeping the optimal efficiency and durability of lift parts. Appropriate lubrication strategies play a crucial duty in avoiding damage on relocating components, decreasing rubbing, and ensuring smooth procedure of the elevator system. When it concerns elevator maintenance, making use of the best lubes in the correct amounts at the suggested periods is vital to preventing expensive repair work and reducing downtime.

To ensure correct lubrication, elevator service technicians must comply with supplier guidelines relating to the type of lube to be utilized for specific elements such as bearings, equipments, and guide rails - lift engineer course. Over-lubrication can draw in dirt and particles, resulting in element breakdowns, while under-lubrication can trigger boosted friction and premature wear. On a regular basis arranged lubrication upkeep ought to be included in the general elevator upkeep strategy to maintain the system running efficiently and securely

Keeping Track Of Deterioration

Elevator upkeep workers must conduct regular inspections to recognize indications of wear on key elements such as ropes, sheaves, guide rails, and bearings. In addition, keeping in-depth maintenance documents can help in tracking the wear patterns of lift components over time, allowing for anticipating upkeep preparation. By carefully keeping an eye on wear and tear, maintenance teams can address problems proactively prior to they intensify right into costly repair services or unforeseen downtime, making sure the effective and safe procedure of the lift system.

Safety Compliance Checks

Carrying out discover here comprehensive safety and security compliance checks is important in guaranteeing the elevator system meets all operational needs and regulative criteria. Safety and security conformity checks involve an extensive exam of various components such as emergency brakes, door sensors, interlocks, and electrical systems to ensure they are working properly. Routine assessments by qualified experts help identify potential safety threats prior to they rise into significant issues, making sure the security of travelers and compliance with market laws. These checks also include confirming that the lift's ability limitations, speed, and emergency communication systems are in line with safety and security criteria. In addition, adherence to safety compliance checks can protect against accidents, reduce responsibility threats for structure proprietors, and expand the life-span of the elevator system. By focusing on safety conformity checks as part of routine upkeep, structure managers can copyright a effective and safe vertical transportation system for owners.

Emergency Feedback Preparation

Taking into account the essential value of security conformity checks in maintaining lift systems, news a robust emergency situation action planning strategy is vital to promptly and properly address unexpected events. lift maintenance company. Emergency situation action planning for lifts entails proactive actions to make sure the safety and security of guests and upkeep workers in the occasion of emergency situations such as power failures, entrapments, or mechanical failings

Secret components of a reliable emergency situation action strategy consist of establishing clear interaction methods, supplying regular training to team on emergency procedures, preserving updated emergency call checklists, and performing routine drills to practice action activities. In addition, it is necessary to have marked personnel accountable for coordinating emergency situation reactions and guaranteeing that needed tools, such as emergency lights and interaction tools, are in working order.

Verdict

Finally, it is critical to focus on routine examination timetables, appropriate lubrication techniques, keeping an eye on wear and tear, safety and security compliance checks, and emergency situation reaction preparation for lift maintenance. By applying these necessary aspects, structure owners can guarantee the safety and security and efficiency of their lifts, eventually decreasing the threat of malfunctions and accidents. Constant maintenance methods are important for extending the life expectancy of elevators and making sure the wellness of people that rely upon them for transportation.

Routinely scheduled lubrication upkeep should be included in the general elevator maintenance plan to maintain the system running effectively and securely.

Lift maintenance personnel need to perform regular examinations to determine indications of wear on vital elements such as ropes, sheaves, guide rails, and bearings. In addition, maintaining comprehensive maintenance documents can assist in tracking the wear patterns of lift components over time, allowing for predictive maintenance preparation. By closely keeping track of wear and tear, upkeep teams can deal with concerns Recommended Site proactively before they rise right into costly fixings or unexpected downtime, making sure the safe and reliable procedure of the elevator system.

Report this page